Capture Everything

Asset Tracking

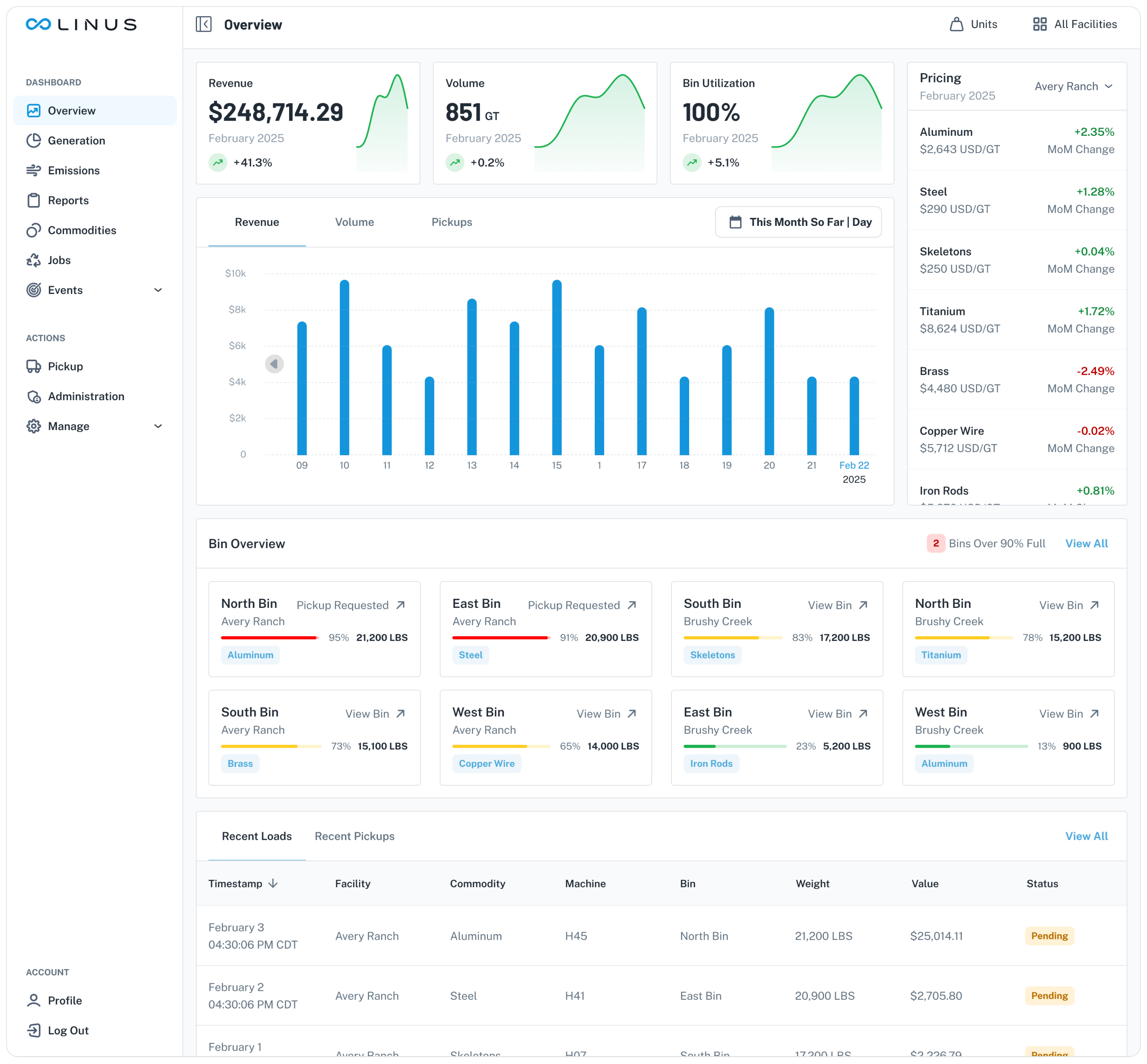

Linus Core autonomously tracks scrap from its origin and directs it to the appropriate roll-off bins, ensuring maximum payloads with every pickup. Precise scrap weights and dollar values are captured for complete accuracy.

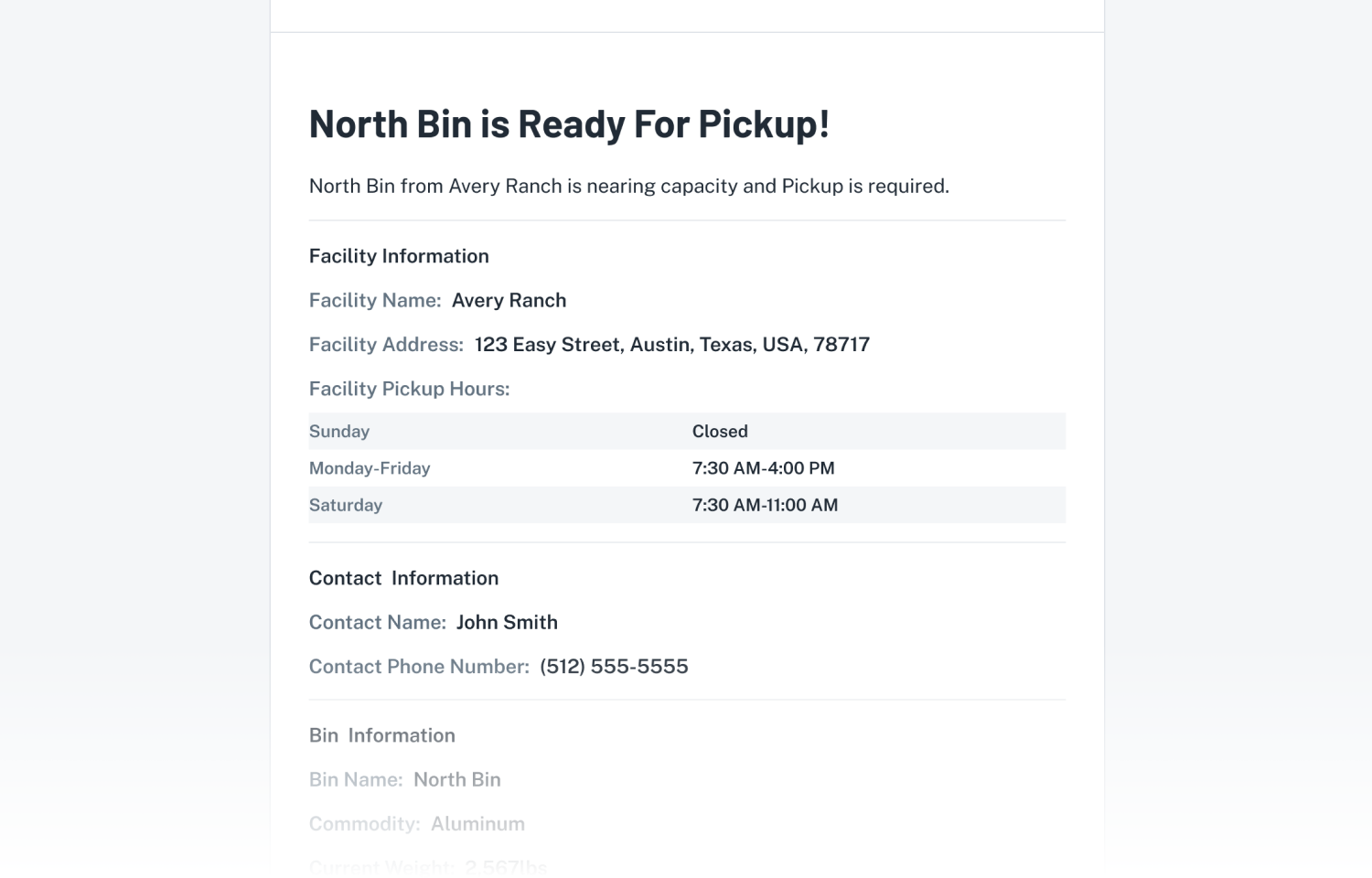

Linus Core autonomously alerts the scrap service provider to pick up scrap bins when their maximum payload is reached.

Chain of Custody

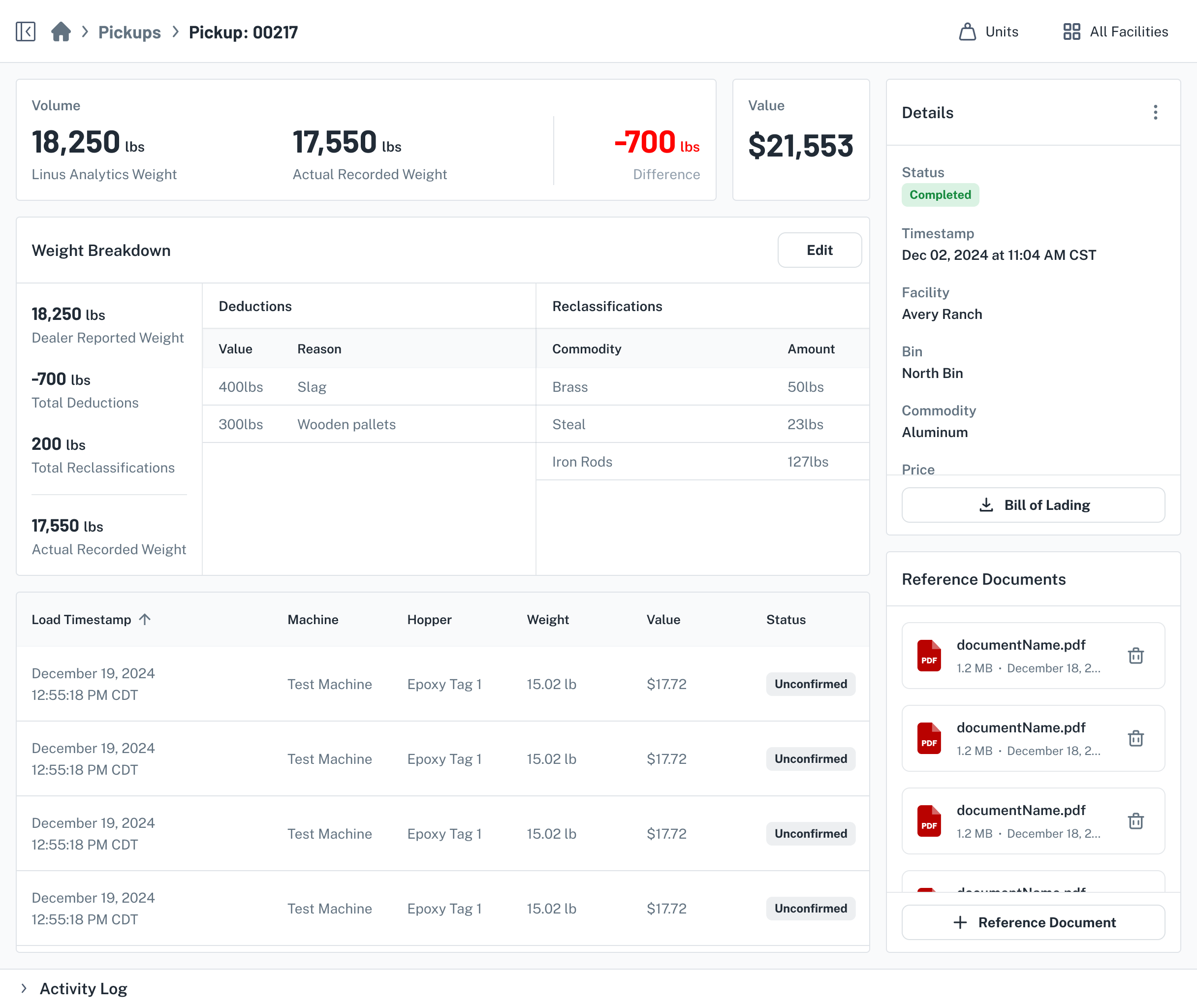

Linus manages your scrap from production to payment, ensuring every pound is tracked and accounted for.

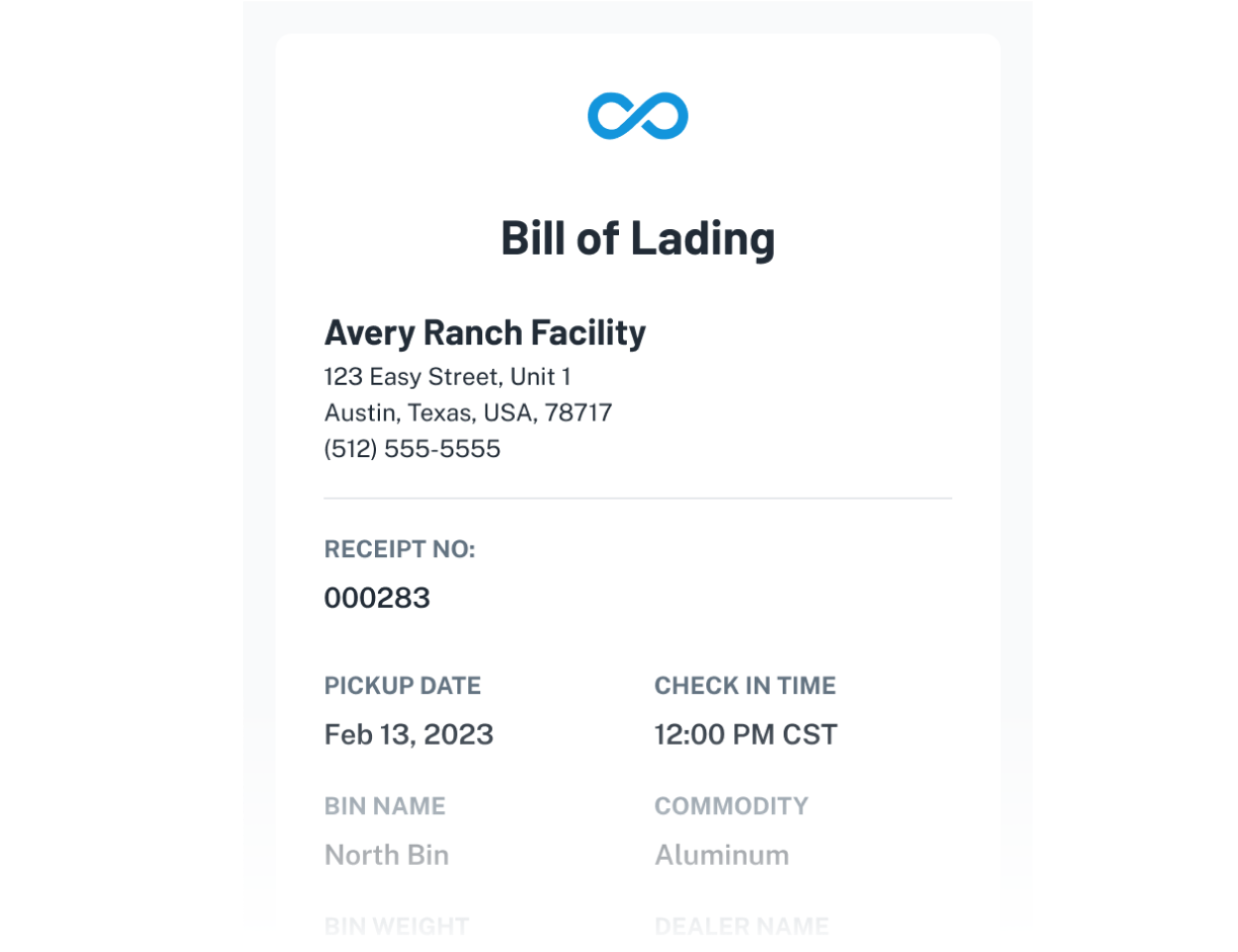

Linus automatically generates a bill of lading for every pickup, authorizing the scrap vendor to remove the asset.

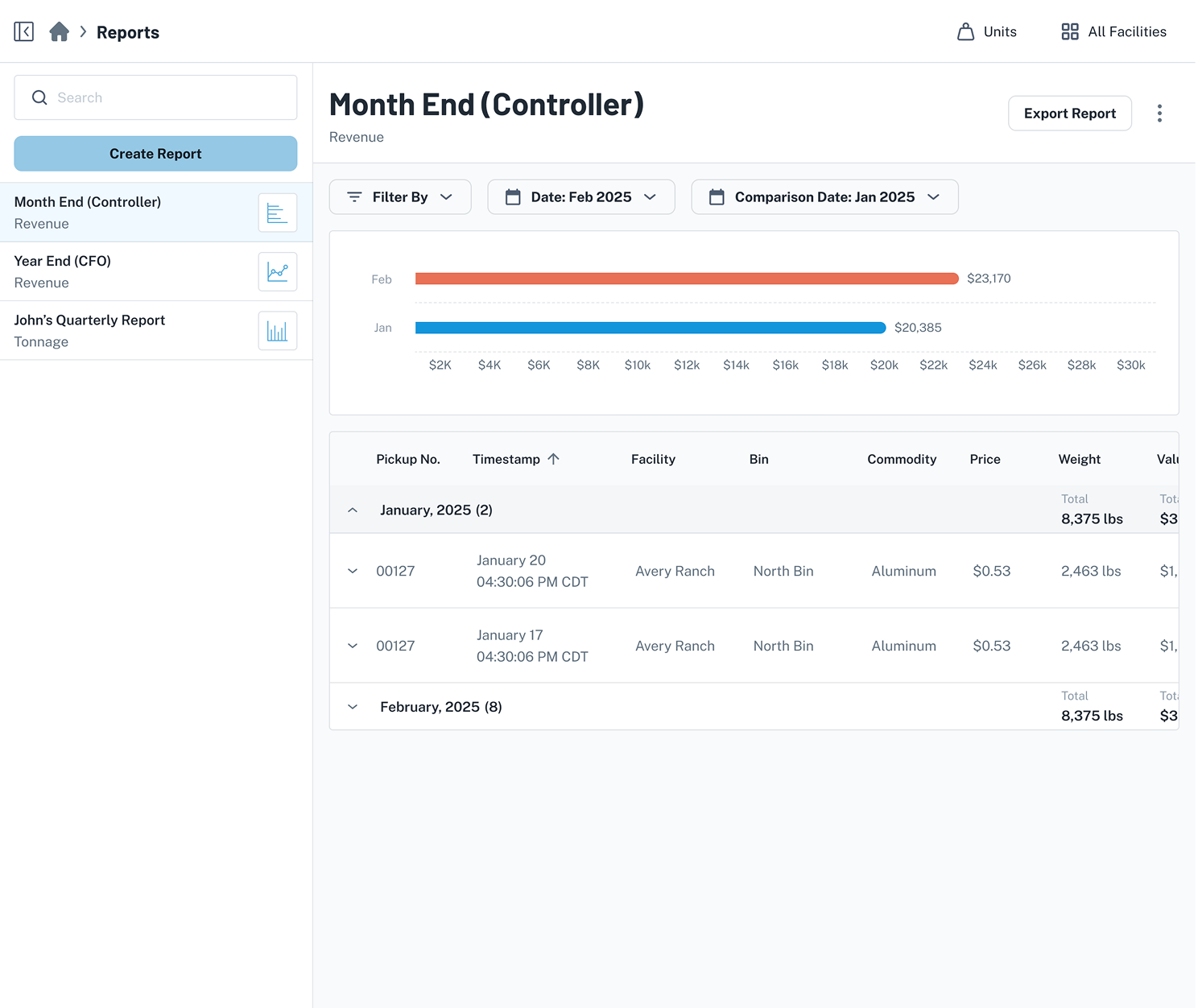

Audit & Compliance

Linus empowers management with instant access to detailed reports for any time period, showcasing all key metrics related to scrap production. Reports can be effortlessly exported to PDF or Microsoft Excel for seamless analysis and sharing.

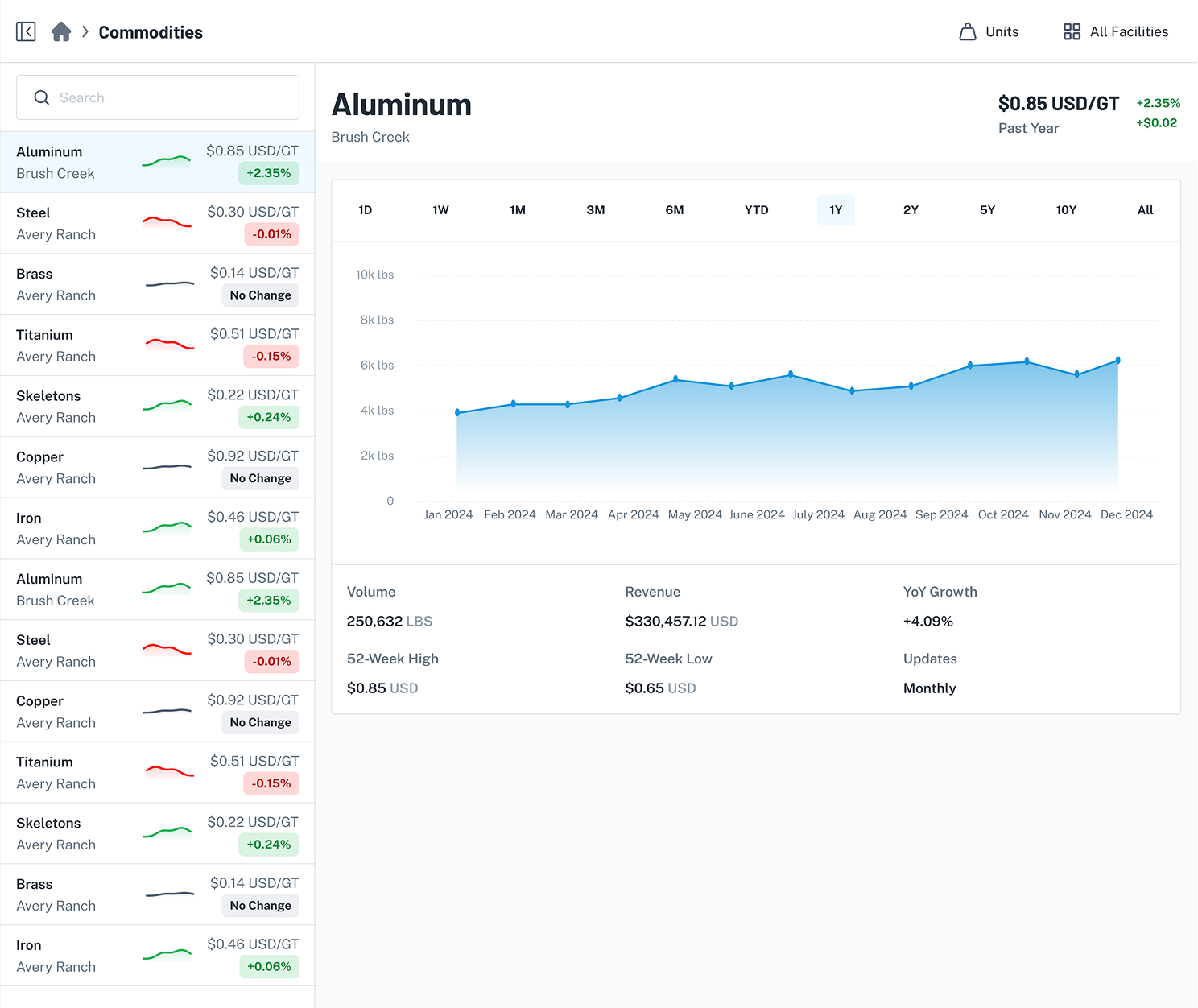

Tracking your scrap's value over time is just one click away, providing complete transparency into pricing and trends.

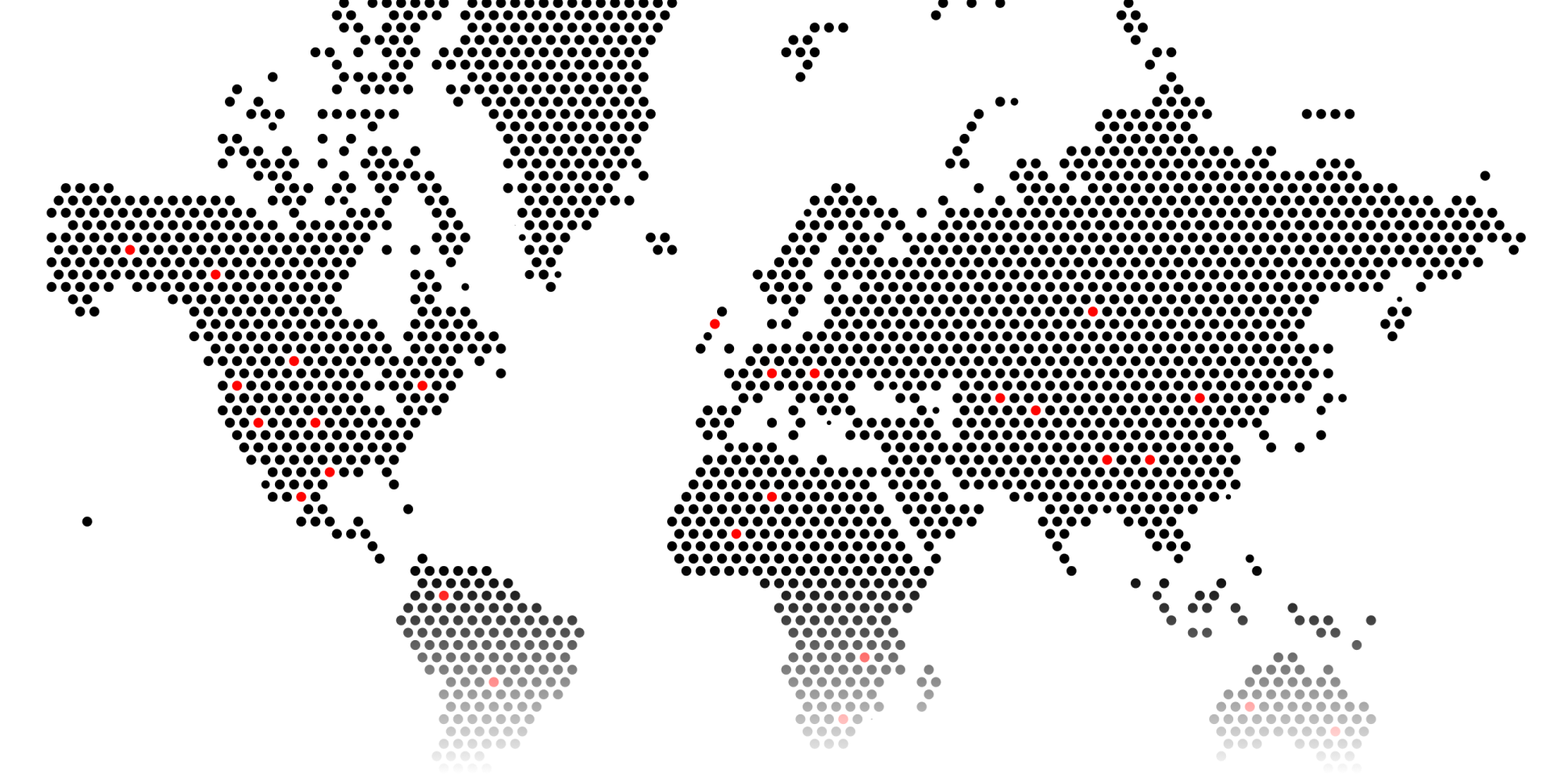

Linus seamlessly integrates data from multiple facilities, delivering enterprise-level insights anytime, anywhere.